Axial fans and EC fans are both widely used in cooling and ventilation applications, but they differ in terms of their motor technology, performance characteristics, and energy efficiency. Understanding the differences between these fan types can help in selecting the appropriate fan for specific cooling requirements. Let’s explore the dissimilarities between axial fans and EC fans.

Axial Fans

Contents

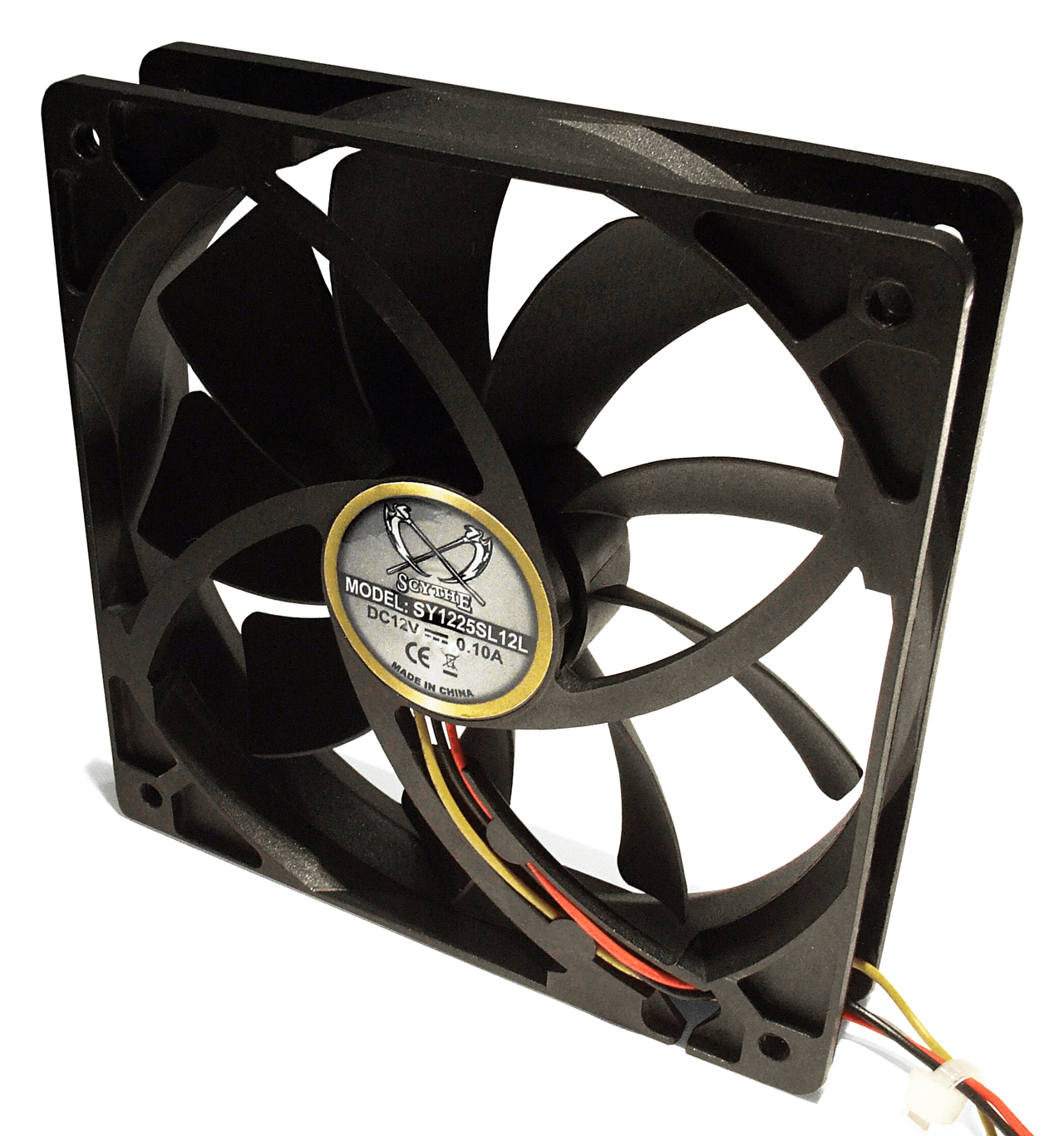

Axial fans are the most common type of fan used for cooling and ventilation purposes. They consist of a hub and a series of blades that rotate around an axis, drawing air in parallel to the fan’s axis and pushing it in the same direction. DC brushless fan 12v 40mm are characterized by the following features:

- Motor Technology: Axial fans typically use traditional AC or DC motors. These motors employ brushes for commutation, which can result in mechanical wear over time.

- Airflow Direction: Axial fans generate airflow in a straight-through direction parallel to the fan’s axis. This design is suitable for applications that require the movement of large volumes of air with lower resistance.

- Performance Characteristics: Axial fans excel in applications that prioritize high airflow volumes. They are efficient at moving air through open spaces or ducts with minimal resistance, making them suitable for cooling electronic components, heat exchangers, and general ventilation.

- Energy Consumption: Traditional axial fans tend to consume more energy compared to EC fans due to their motor design and lack of advanced control systems.

EC Fans

EC fans, also known as electronically commutated fans, are a type of fan that utilizes brushless DC motor technology. These fans are designed to provide improved energy efficiency, precise speed control, and reduced noise levels. The key features of EC fans include:

- Motor Technology: EC fans incorporate brushless DC motors. These motors use electronic circuitry to control the motor’s operation, eliminating the need for brushes and resulting in reduced mechanical wear.

- Airflow Direction: EC fans also generate airflow in a straight-through direction parallel to the fan’s axis, similar to axial fans. This allows them to effectively move air through ducts or open spaces.

- Performance Characteristics: EC fans offer the advantages of variable speed control and precise airflow management. The electronic control system allows for optimized speed adjustments, resulting in energy savings and quieter operation.

- Energy Efficiency: EC fans are known for their energy efficiency. The electronic control system allows for precise adjustment of fan speed according to specific cooling requirements, minimizing power consumption.

Differences Between Axial Fans and EC Fans

The main differences between axial fans and EC fans can be summarized as follows:

- Motor Technology: Axial fans typically use traditional AC or DC motors with brushes, while EC fans utilize brushless DC motors. The brushless design of EC fans contributes to increased reliability and reduced mechanical wear.

- Speed Control: EC fans offer precise speed control, allowing for optimized airflow management. Axial fans generally have limited speed control options.

- Energy Efficiency: EC fans are more energy-efficient compared to axial fans. The advanced motor control technology of EC fans results in reduced power consumption and improved overall efficiency.

- Noise Levels: EC fans operate at lower noise levels compared to axial fans. The advanced motor control and reduced mechanical wear in EC fans contribute to quieter operation.

- Cost: Due to their advanced motor technology, EC fans tend to have a higher initial cost compared to axial fans. However, the energy savings and performance benefits they provide can result in cost savings over time.

Conclusion

Axial fans and EC fans are both valuable for cooling and ventilation applications, but they differ in terms of motor technology, speed control, energy efficiency, noise levels, and cost. Axial fans are known for their high airflow volumes, while EC fans offer the advantages of precise speed control and energy efficiency. By considering the specific cooling requirements and priorities, one can make an informed decision on whether to choose an axial fan or an EC fan for a particular application.

FAQs (Frequently Asked Questions)

Can an axial fan be replaced with an EC fan in an existing system?

Yes, in many cases, an axial fan can be replaced with an EC fan in an existing system. However, considerations such as electrical compatibility, physical dimensions, and control interfaces should be taken into account during the replacement process. Consulting with a qualified professional is recommended to ensure a successful fan replacement.

Which fan type is more suitable for cooling electronic components?

Both axial fans and EC fans are suitable for cooling electronic components, but EC fans offer the advantages of energy efficiency, precise speed control, and reduced noise levels. These features make EC fans a preferred choice in applications where efficient cooling and precise temperature management are crucial for maintaining optimal performance and longevity of electronic components.

Do EC fans require any special control systems?

EC fans come with integrated electronic control systems that allow for precise speed control and optimized airflow management. These control systems may require additional interfaces or protocols to interact with the fan and adjust the speed according to specific cooling requirements.

Are axial fans more cost-effective than EC fans?

Axial fans generally have a lower initial cost compared to EC fans due to their simpler motor design. However, it’s important to consider the long-term cost savings associated with the energy efficiency of EC fans. Over time, the reduced power consumption of EC fans can result in significant energy savings, offsetting the initial higher cost.

Which fan type is quieter, axial fans or EC fans?

EC fans are typically quieter compared to axial fans. The advanced motor control technology in EC fans helps minimize vibration and noise generation, resulting in quieter operation. This makes EC fans suitable for applications where noise levels need to be kept to a minimum, such as in noise-sensitive environments or residential settings.

Can both axial fans and EC fans be used in HVAC systems?

Yes, both axial fans and EC fans can be used in HVAC (heating, ventilation, and air conditioning) systems. Axial fans are commonly used in HVAC systems for general ventilation and air circulation, while EC fans are preferred in HVAC systems that require energy-efficient operation, precise temperature control, and reduced noise levels.

Are EC fans suitable for outdoor applications?

Yes, there are EC fans specifically designed for outdoor applications. These fans are built to withstand environmental factors such as dust, moisture, and temperature fluctuations, making them suitable for outdoor installations where efficient cooling and ventilation are required.

Can the speed of an axial fan be adjusted?

While axial fans generally have limited speed control options compared to EC fans, some models may offer speed control features. However, the range of speed adjustment and control mechanisms may be more limited compared to the precise speed control capabilities of EC fans.

Do EC fans require regular maintenance?

EC fans generally require minimal maintenance. Regular cleaning of the fan blades and housing to remove dust and debris is recommended to ensure optimal performance and airflow. It’s important to follow the manufacturer’s maintenance guidelines for specific EC fan models.

Which fan type is more suitable for applications with space constraints?

EC fans are often more suitable for applications with space constraints due to their compact design. The brushless motor technology of EC fans allows for a more streamlined and compact fan construction, making them ideal for installations where space is limited, such as in compact electronic devices or equipment with confined spaces.